1

HOME > Interviews >

IN CONVERSATION WITH SIMON COTTON OF JOHNSTONS OF ELGIN

Written by Menswear Style in Interviews on the 12th June 2020

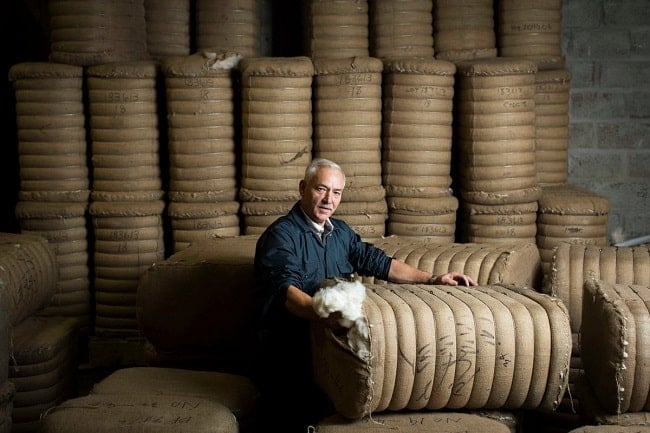

With a history of working in the textiles industry and other manufacturing industries, Simon Cotton is proud to be currently heading up the most exciting company in the UK textile industry. Johnstons of Elgin partner with most of the world's top luxury fashion brands as well as produce under their own label. The company is a truly vertical producer taking raw fibre through to finished product, allowing them to achieve the very highest quality for the most discerning customers across the world.

Johnstons of Elgin has over two hundred years of tradition and experience in textile manufacturing. Since 1797 the company has produced the finest woven products from the finest of fibres. The original mill, on the banks of the river Lossie in the historic town of Elgin, remains the headquarters of their renowned brand. From luxurious cashmere scarves and throws, to historic Estate tweed, the experience and craftsmanship rooted in their history has been passed down the generations. Visitors to the mill see experienced craftsmen producing luxury pieces using traditional methods. Their knitwear mill in Hawick, in the Borders, sits in the heart of the Scottish knitting industry. An important part of the local community for over thirty years, the long history of knitwear production in that part of Scotland, ensures their knitted garments are made with the utmost skill and expertise. A unique family business with tradition and heritage at its core, Johnstons of Elgin promises to continue pushing the boundaries of textile and knitwear manufacturing, while always remaining true to its history.

In a recent episode of the MenswearStyle Podcast we interviewed Johnstons of Elgin CEO, Simon Cotton, about the company's manufacturing as a private label to luxury brands as well as their own brand. Best known as a manufacturer, they've been establishing their own brand name with brick and mortar store openings and a focus on digital over recent years. Our host Peter Brooker and Simon discuss how cashmere is produced, the day-to-day of a Chief Executive, the benefits of holding a royal warrant and how the current global Coronavirus pandemic has affected their retail and manufacturing operations.

Please tell us about what you do and how the company is currently trading?

“I’m the Chief Executive and have been for 6 years. Our entire operation consists of two major manufacturing plants where we make woven and knitted products. We also have our own retail, and coffee shops, but the majority of our business is manufacturing for some of the world’s top luxury brands. We’re the largest white label supplier to luxury brands and around a third of our business is our own brand. We don’t talk about them but if you imagine the best luxury brands that you see on London’s Bond Street, we’re probably supplying around two thirds of those.”

Where is the Cashmere sourced from?

“You get a tiny amount from every Cashmere goat – approx. two hundred grams on average – so there needs to be a huge grazing area for Cashmere. It’s generally grown in Mongolia and Afghanistan over a vast area. It tends to be poor land that is not suitable for much else. They have really extreme winters which makes the fibres very thin, fine and soft. This gives the animal a lot of protection during the winter and then they are combed during the springtime. It’s a very long traditional process that has been going for hundreds of years. It’s not something we could do in scale here in Scotland, but there has been attempts before, but the climate tends to be a little too warm here. You really do need those extreme temperatures of minus thirty, or alternatively, you need very good genetics. There’s some really good work being done with a small herd in England and New Zealand to develop those genetics.”

How is the flagship store performing?

“London has been very good for us. We’ve best been known as a manufacturer and we’ve been developing the brand over the last five to six years. We establish the Bond Street store a few years ago and it was considered a risk at the time by us. But what was really gratifying was that our customers asked why it had taken so long. We were known as the best kept secret in textiles manufacturing - the brand behind the brands - for many years. The store helps people understand what the whole Johnstons of Elgin brand does because a lot of our customers come to us on a specific category, and for the first time we could showcase everything such as socks, jackets, coats, knitwear, and accessories which is what we’re best known for. It was a chance for everybody to see all that in one place, and that has been very helpful.”

This is a shortened transcribed edit of episode 62 of the MenswearStyle Podcast with Simon Cotton, CEO of johnstonsofelgin.com. You can listen to the full version below or listen on Apple Podcasts, Spotify or your favourite podcast player.

Trending

2

3

4

5

6

7

8

9

10