1

HOME > Trends >

INTRODUCING CIRCULAR FASHION WITH TEEMILL

THE FUTURE, REMADE.

Written by Menswear Style in Trends on the 16th May 2019

Every year 100 billion new items of clothing are produced while a truck full of clothing is burned, or buried in a landfill every second. Slowing fast fashion down a bit won't fix it. But when we take the waste material at the end, and make new products from it at the start, it changes everything. That's what Teemill have done. Their products and packaging are made from natural materials, not plastic. And every product they make is designed to be sent back to them when it is worn out. They make new products from the material they recover, and the cycle itself is renewable. Teemill products can be returned and remade again and again and again. A pure material makes remanufacturing possible, and means products that are softer, and not harmful to the environment.

Remanufacturing

Teemill's technology automates the complex decision making required to run a real time supply chain for the tens of thousands of startups, brands and charities connected to their factory via the cloud. In their modern process, products are only made in real time - in the seconds after they are ordered - so there is no waste inventory. Huge problems call for huge solutions. So they created a platform to share access to their circular supply chain online. Teemill means that anyone with an internet connection can use their systems, for free, and start their own brand. Like Airbnb or Uber, modern technology is disrupting the fashion industry and for them, conscientious application means they can make sustainable fashion a reality. The future of fashion is circular, and Teemill are building it on the cloud today.

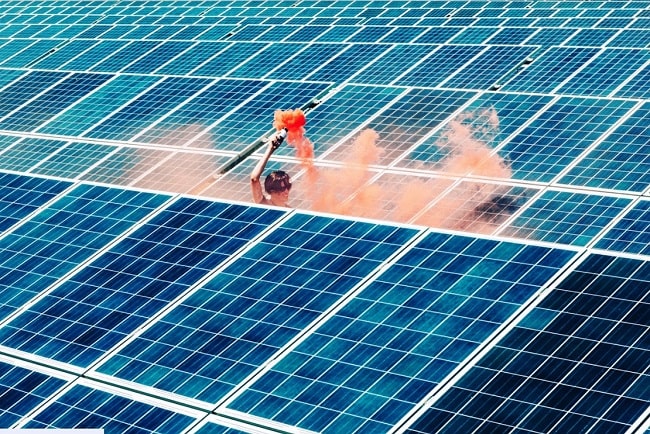

Renewable Energy

Throughout our supply chain renewable energy is used. In the UK we own a solar farm and power our manufacturing operations with renewables including our on-site solar farm. In India, the factory owns two wind farms and a 150kw PV array. Within our factory we use machine-to-machine communications technology which allows us to dynamically turn equipment on and off only when it is needed.

Customers scan the label inside with their phone to activate a free post returns coupon when the product is worn out. Teemill recover and remanufacture the materials into new t-shirts and give the customer £5 off a new item. Technology efficiencies enable these plastic free, organic and recycled t-shirts to be retailed new at £20. Customers are incentivised to keep the material flowing with money off their next purchase, Teemill benefits from lower material costs and the model is truly sustainable. It’s a circular fashion economy where everybody wins.

Trending

2

3

4

5

6

7

8

9

10